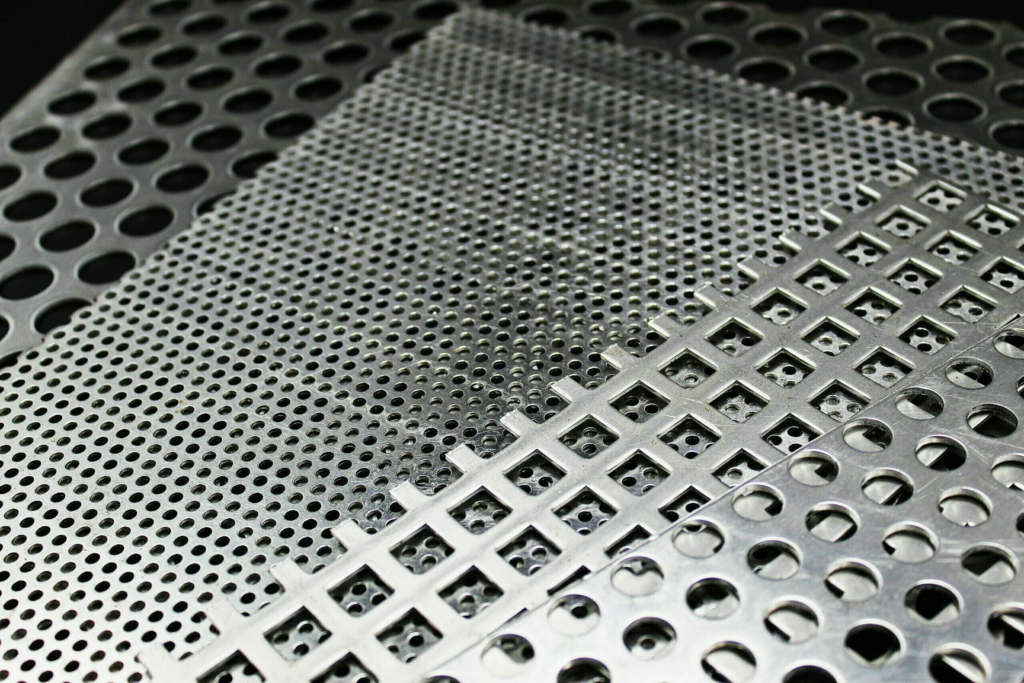

Looking for anything created from metal that fits your needs throughout the spectrum of weight, durability, and aesthetics? Solution: perforated aluminum sheet panels. Perforated aluminum sheet panels combine high-end design and practicality for interior and exterior designs. They may have punched holes for better aesthetics, water drainage, light control, acoustic aspects, and privacy applications.

You may get a perforated aluminum sheet in a range of dimensions. Staggered hole patterns are the most common and may be found in full and cut sheet sizes.

Features of Using Perforated Aluminum Sheet

- It has a strong visual appeal, making it the material of choice for architects all around the globe.

- The room’s acoustic performance is improved due to its increased soundproofing, decreased emissions, and eliminated echoes. Because sound waves go through it unchecked, it may be utilized as a sound absorber in acoustic equipment enclosures.

- Perforated sheets are stronger and lighter than solid ones. It’s lighter and simpler to transport, which may help relieve a lot of stress on buildings. Transportation expenses are cut in half as a result. It’s also resistant to many climate conditions and far stronger than many common construction materials.

- It outperforms most metal sheets in terms of flexibility, versatility, energy efficiency, and construction performance. The fact that it can be recycled shows that its designers care about the planet.

Advantages of The Perforated Aluminum Sheet

The Aluminum Core Panels can be used for many things, like building houses, covering roofs, cladding, etc. They have many advantages over other building materials, which is why they are used in almost all building projects in urban and metropolitan areas.

Among the many benefits of ACP sheets, the following have been mentioned:

- Cost-effective: Compared to other options like steel plates, insulated coverings, etc., they are very cheap and economical. When bought from wholesalers and sheet distributors in the area, you Can have them for a low price. They also cost very little to keep up, so customers can use them for many years without paying extra money.

- Long-Lasting Life: The average PAS panel lasts more than 10 years after it is bought, which means it is a good long-term investment. They keep the house safe from the sun, rain, and termites for many years without getting damaged or losing quality.

- Fire-Resilient: These cheap alternatives to an insulated covering are fire-resistant and can’t catch on fire, so customers don’t have to worry about their homes’ safety. They also keep the inside of the building safe from fires, gas leaks, etc.

- Low Cost of Maintenance: These PAS sheet panels have very low maintenance costs and aren’t likely damaged by things like termites, water, sunlight, etc. Maintenance costs are so low that a customer who buys these panels from the market will spend almost nothing on maintenance for the next 5–10 years.

- Easy to Put Up: These sheets are easy to put up in your homes by fitting and shaping them. Only a small charge is required for the services needed to put these panels in your homes. Most of the time, the sellers install these protective aluminum coverings at their customers’ homes for free or for a very small fee.

- Weather Resistance: They can stand up to rain and sun, damaging houses in some places. The furniture and electronics in your house will be safe from termites because these panels are resistant to them. They can also stand up to high and low temperatures, making them great for any weather in the future.

The PAS panels usually make your house look better, but if you choose the right shapes and colors, you can use these aluminum covers to give your house a new look. Can bring The best patterns to the walls of your homes with the right colors and textures. These panels also come in a wide range of sizes, which can be important when using them to design the looks of your homes.

Disadvantages of Aluminum Perforated Sheet

There are no bad effects of using perforated aluminum, but some drawbacks of this metal are discussed below:

- They can get dents during storms and hurricanes, which is the biggest problem. Some companies that make Aluminum Composite Panels add special threads to the panels to protect them from this damage.

- Must meticulously seal joints, and the building has to be waterproofed well enough so that water doesn’t get in when it rains.

Uses of Perforated Aluminum Sheet

Perforated Aluminum sheets are used in several sectors and markets, including:

- The construction industry: These sheets are used to create signboards, ventilation grilles, facades, temporary airfield surfaces, acoustic panels, pipe guards, and stair treads, among other items.

- Automotive: These aluminum screens have been used in the automobile industry to manufacture different ventilation components, grids, silencer tubes, radiator grills, boards, floors, air and oil filters, and so on.

- Chemical and Electrical: This industry employs aluminum sheets for various cleaners, filters, washing equipment, drying baskets, battery separator plates, liquid gas-burning tubes, and water screens, among other applications.

- Creation of Materials: In addition to other new materials, perforated aluminum sheets are utilized in various machinery, including printers, mills, cinder screens, blast furnace screens, glass reinforcements, and screens for cement slurry.

- The drinks and foods: Construction of hives, sorting equipment, juice filters, baking trays, coffee screens, grain dryers, wine vats, silo ventilation, and other food industry equipment are all made using perforated aluminum sheets.

- Architectonic: Architecture is one of the most important uses for perforated aluminum sheets. It has many uses, including site amenities, cladding, infill panels, sunshades, metal signage, fence screens, and column wraps.

Conclusion

Aluminum perforated sheet is lighter than perforated steel sheet and stainless steel perforated sheet. It is also good at resisting corrosion and is easy to weld and shape. The perforated Aluminum sheet has different hole sizes, spacing, and thicknesses. When you order from Online Metals, you can choose between standard sizes or sizes cut to your specifications. Don’t forget to use U-edge trim to finish your project with perforated aluminum sheets.

We hope you found this post interesting. If you want to see more of our content, you can visit our website Wehomedeco.com for more articles, tips, and resources. You can also follow us on social media to stay updated with our latest posts . We would love to connect with you and hear your feedback. Here are our social media links: